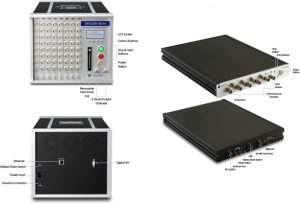

Spider-80X

The Spider-80X is designed for applications in three fields: dynamic data acquisition, vibration control, and machine monitoring.

Each front-end features an eight analog input channels and two channels that may be software selected as analog outputs for vibration control or tachometer inputs for the analysis of rotating machinery.

A single Spider-80X front-end is a complete two output controller with the same high quality patented dual ADC input technology of the Spider-81 series. The Spider-80X inputs provide single end/differential and AC/DC/IEPE coupling choices; charge mode is an available option that can be installed at the factory. The Spider-80X also provides the same time sync Ethernet connectivity and 4GB flash memory for data and program storage. Multiple Spider-80X front-ends may be linked together using the Spider-HUB Ethernet switch from Crystal Instruments. The data storage can be increased to 250 GB by adding a Spider-NAS mass storage device.

The Spider-80X front-ends are onsite swappable. Each front-end is metal-shielded. The user can quickly configure a system with an arbitrary number of front-ends. Spider-80X, multiple chassis combine to create a system up to 512 channels, all sampled simultaneously. A dedicated massive storage hard disk (a solid state hard-drive with a capacity of 250GB) allows the time signals of all input channels to record at up to 102.4 kHz/channel. Accurate time synchronization results in excellent phase match in the frequency domain between all channels, either on the same Spider front-end or across different front-ends. Real time FFT, octave, order tracking or vibration control functions can be enabled.

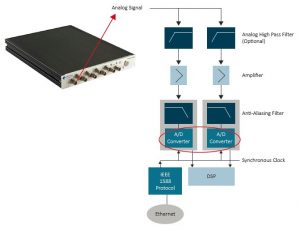

High Precision Front-end Design

The Spider-80X analog input channels provide extremely high precision measurements. Each channel has single-ended or differential AC or DC input coupling. It can also provide IEPE (ICPTM) input mode (AC coupling with a 4-mA constant current from a 22 VDC source) for use with industry-standard accelerometers with built-in amplifiers. The ability to read TEDS (Transducer Electronic Data Sheet) identification from the attached transducer completes the channel’s compliance with IEEE 1451.4. Each channel provides an unprecedented dynamic range of 160 dBFS, detecting voltages as small as 600 nV and up to 20 V.

Black Box Mode

Black Box mode enables Spider-80X operation without a PC. In this mode, a PC is used only to configure the control system before the system starts operation and to download data after the test is completed. During the test, the data acquisition system operates autonomously, according to a preset schedule or in response to external events such as input trigger or digital input.

| Spider-80X | Spider-80Xi | |

|

|

||

| Total Channels Per System | 8 to 512 | 8 to 512 |

| Input Mode | AC, DC, IEPE (ICP®), optional charge | AC, DC, IEPE (ICP®) |

| Charge Amplifier Solution | Internal charge can be installed at the factory

Can use external amplifier |

Use external charge amplifier |

| Main Application | Vibration control, dynamic testing, remote monitoring

8 to 512 channels |

Portable dynamic signal data acquisition and real-time processing with relatively large channels. Some applications may require battery power |

| Software Applications | VCS, DSA, RCM | DSA, RCM |

| Strain Gage | Can install strain gage front-end in the same chassis | N/A |

| Modularity | Front-end is shielded with its own chassis hence swappable on site | Board modules are installed at factory and are not swappable |

| Weight of 8 Channel Front-end | 2 kg | N/A |

| Dimension of 8 Channel Front-end | 240 x 35 x 310 mm (w x h x l) | N/A |

| Weight of a 32 Channel System | 23 kg for 32 channels 25 kg for 40 channels |

8 kg |

| Dimension of a 32 Channel System | 343 x 310 x 407 mm (w x h x l) | 194 x 259 x 298 mm (w x h x l) |

| Weight of a 64 Channel System | 36.5 kg | 10.4 kg |

| Dimension of a 64 Channel System | 470 x 310 x 407 mm (w x h x l) | 274 x 259 x 298 mm (w x h x l) |

| Power of a 64 Channel System | AC powered, 100W | AC powered, 90W |

| Power of a 32 Channel System | N/A | DC powered, 50W |

| Battery Power | N/A | Available (with Spider-Battery) |